HPV

This product is compatible with manual needle valves and digital kits.

Customized solutions for other types of manual needle valves are also available—please feel free to contact us.

Product Overview

The HPV manual needle valve (with a visualized control solution) is an innovative product developed by the KIYAN team to address the needs of traditional industries.

In industrial settings, conventional needle valves are widely used for flow or pressure regulation, but they often require long periods of manual adjustment by operators. The adjustment results typically depend on the operator’s experience, lacking consistency and digital control capabilities.

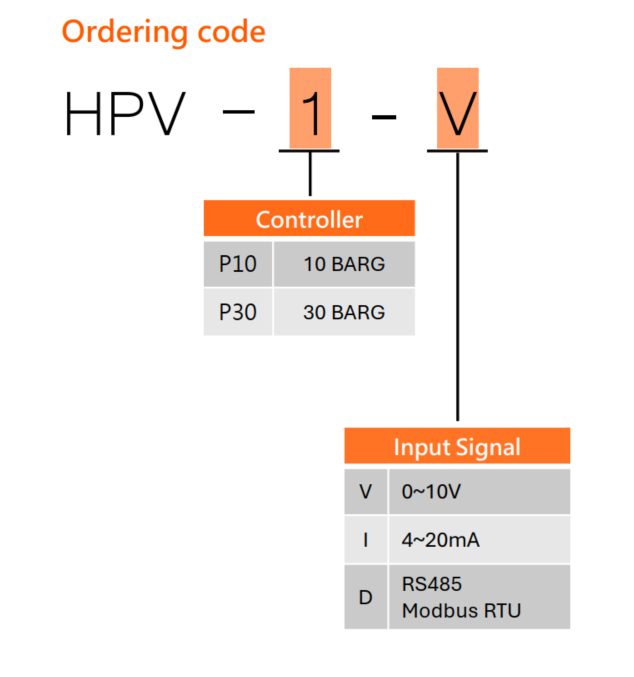

To solve this issue, we developed a simple digital upgrade solution: by removing the manual handle and installing a stepper motor on the shaft, combined with our controller, the needle valve’s opening can be precisely controlled via digital signals (0–10V, 4–20mA, RS485).

The product also features a built-in position sensor, allowing real-time monitoring of valve operation to ensure complete closure, prevent step loss, and greatly improve reliability and ease of use.

This solution transforms traditional manual needle valves into smart, automated proportional valves, enabling production lines to quickly implement digital upgrades.

Main Features

- Quick Upgrade

Simply replace the handle to instantly digitalize a traditional manual needle valve. - Precise Control

Supports analog and digital signal inputs for accurate valve opening adjustment. - Position Feedback

Built-in sensor provides real-time monitoring of valve position, preventing step loss and ensuring complete closure. - Reduced Reliance on Manual Operation

Prevents inconsistent adjustments caused by differences in operator experience. - High Versatility

Compatible with various types of needle valves, allowing for easy installation. - Smart Integration

Compatible with PLC and industrial control systems, enhancing overall automation capabilities.

Applications

- Digital Upgrade for Traditional Factories

Quickly convert existing manual needle valves into digitally controlled units. - Automated Production Lines

Suitable for gas/liquid flow control, reducing manual intervention. - Semiconductor & Electronics Industry

Applications requiring precise needle valve flow adjustment in process equipment. - Laboratories & R&D Units

Provides digital control and stable, repeatable adjustment capabilities. - Energy & Emerging Industries

For applications requiring traceable fluid control environments, such as hydrogen energy and battery manufacturing processes.

| Modle | HPV-0-☐ | HPV-1-☐ |

| Thread | HPV-0/1-☐ : 1/4G” | |

| HPV-0/1-☐ : 3/8G” | ||

| Power Supply | Voltage | DC 24V ± 10% |

| Power | ≤24W | |

| Input Signal | Voltage Type | 0~10V |

| Current Type | 4~20mA | |

| Digital Type | RS485 (modbus RTU) | |

| Input Impedance | Voltage Type | 4kΩ |

| Current Type | 250Ω | |

| Electrical Connection | 4-pin Pluggable Screw Terminal Back | |

| Repeatability | ±0.1% F.S.(Full Stroke) | |

| Response Time | 0.8s @(Full Stroke)*10% | |

| Display Accuracy | ±0.3% F.S.(Full Stroke) | |

| Ambient Temperature | 0~60℃ | |

| Fluid Temperature | 0~60℃ | |

| Protection Rating | IP40 | |